1. Ukufakwa kweminwe

In Ubungqina bePCB, iintsimbi ezinqabileyo zifakwe kwibhodi yebhodi yesixhumi somphetho, ibhodi ephethe uqhagamshelwano oluphumayo okanye umnwe wegolide ukubonelela ukuchasana okuphantsi kunye nokumelana nokunxiba okuphezulu, okubizwa ngokuba yi-finger plating okanye i-protruding plating yendawo.Inkqubo imi ngolu hlobo lulandelayo:

1) hlubula i-coating kwaye ususe i-tin okanye i-tin lead i-coating kwi-contact ephumayo.

2) ukuhlamba ngamanzi.

3) khuhla nge-abrasive.

4) ukusebenza kusasazeka kwi-10% ye-asidi ye-sulfuric.

5) Ubukhulu be-nickel plating kuqhagamshelwano oluphandle yi-4-5 μ m.

6) Ukucoca ukususa amanzi amaminerali.

7) ukulahlwa kwesisombululo segolide.

8) ukufakwa kwegolide.

9) ukucoca.

10) ukomisa.

2. Ngeplating

Kukho iindlela ezininzi zokuseta umaleko ofanelekileyo we-electroplating kudonga lomngxuma we-substrate yokomba, obizwa ngokuba kusebenze udonga lomngxuma kwizicelo zoshishino.Inkqubo yokusetyenziswa kwezorhwebo yesekethe yayo eprintiweyo idinga iitanki ezininzi zokugcina eziphakathi, nganye yazo ineemfuno zayo zokulawula nokugcina.Nge-electroplating yinkqubo elandelayo yokwenziwa kwemfuneko yenkqubo yokuvelisa ukomba.Xa intwana yokomba igqobhoza kwifoyile yobhedu kunye nesubstrate engaphantsi, ubushushu obuveliswayo budibanisa intlaka ekhuselayo eyenziweyo eyenza uninzi lwe substrate, kunye nentlaka econdensed kunye nobunye ubumdaka bokomba buqokelelana malunga nomngxuma kwaye bugqunywe kudonga lomngxuma osandula ukuvela. kwi-foil yobhedu, kunye ne-resin edibeneyo iya kushiya umgca we-axis eshushu kudonga lomngxuma we-substrate;Ibonisa ukubambelela kakubi kwii-activators ezininzi, ezifuna ukuphuhliswa kohlobo lwethekhnoloji efana nesenzo sekhemikhali sokususwa kwamabala kunye ne-corrosion back.

Eyona ndlela ifaneleke ngakumbi yokungqinisisa i-PCB kukusebenzisa i-inki eyilwe ngokukodwa eye-viscosity esezantsi, encamathelayo eyomeleleyo kwaye inokubotshelelwa ngokulula kwezona ndawo zininzi zishushu ezikhazimlisiweyo zendonga, ngaloo ndlela ishenxisa inyathelo le-tchback.

3.I-roller idityaniswe neplating ekhethiweyo

Izikhonkwane kunye nezikhonkwane zoqhagamshelwano zamacandelo e-elektroniki, njengeziqhagamshelo, iisekethe ezidibeneyo, ii-transistors kunye neesekethe eziprintiweyo eziguquguqukayo, zikhethwa ngokufanelekileyo ukufezekisa ukuchasana koqhagamshelwano kunye nokuxhathisa ukubola.Le ndlela ye-electroplating ingaba yincwadana okanye ngokuzenzekelayo.Kubiza imali eninzi kakhulu ukumisa i-plating ekhethiweyo yephini nganye, ngoko ke kufuneka kusetyenziswe ibhetshi yokuwelda.Ekukhetheni indlela yokucwenga, qala unxibe umaleko wefilimu ye-inhibitor kwiindawo zefoyile yobhedu yesinyithi engadingi i-electroplating, kwaye uyeke kuphela ukufakwa kwe-electroplating kwifoyile yobhedu ekhethiweyo.

4.Ukufakwa kwebrashi

I-brush plating iteknoloji ye-electrostacking, eyeka kuphela i-electroplating kwindawo elinganiselwe kwaye ayinayo impembelelo kwezinye iindawo.Ngokuqhelekileyo, iintsimbi ezinqabileyo zifakwe kwiindawo ezikhethiweyo zebhodi yesekethe eprintiweyo, njengeendawo ezifana nezixhumi zomphetho webhodi.Ukufakwa kwebrashi kusetyenziswa kakhulu kwindawoiindibano zocweyo ze-elektronikiukulungisa iibhodi zeesekethe zenkunkuma.

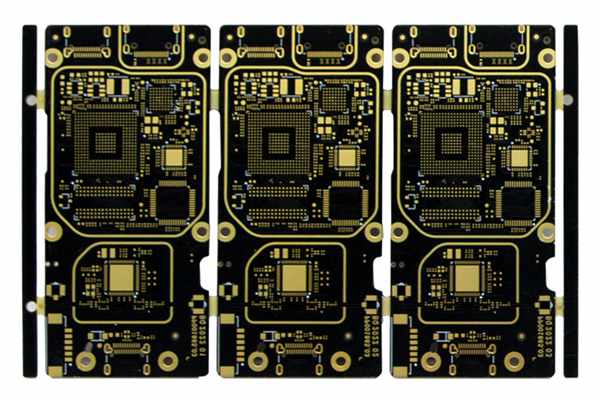

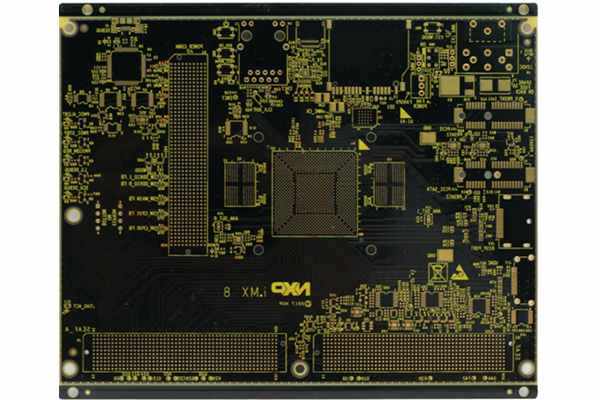

I-PCBFuture yakha igama lethu elihle kwishishini lenkonzo ye-PCB ye-turnkey epheleleyo yendibano ye-PCB yomzekelo kunye nomthamo ophantsi, indibano ye-PCB yevolumu ephakathi.Yintoni ekufuneka abathengi bethu bayenze kukuthumela iifayile zoyilo zePCB kunye neemfuno kuthi, kwaye sinokukhathalela wonke umsebenzi.Sikwazi ngokupheleleyo ukubonelela ngeenkonzo zePCB ezingenakoyiswa kodwa sigcine iindleko zizonke kuhlahlo lwabiwo-mali lwakho.

Ukuba ujonge umenzi wendibano weTurnkey PCB ofanelekileyo, nceda uthumele iifayile zakho zeBOM kunye neefayile zePCB ku sales@pcbfuture.com.Zonke iifayile zakho ziyimfihlo kakhulu.Siza kukuthumelela ikhowuti echanekileyo kunye nexesha lokukhokela kwiiyure ezingama-48.

Ixesha lokuposa: Dec-13-2022