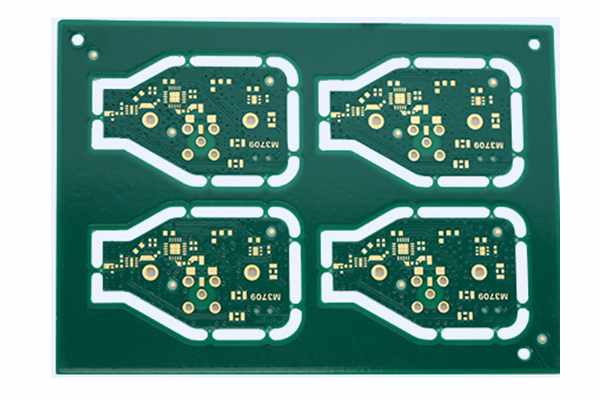

1. Ukusika

Jonga ukucaciswa, imodeli kunye nobungakanani bokusika kwebhodi ye-substrate ngokwemveliso yemveliso okanye imizobo yokusika.I-longitude kunye ne-latitude ye-latitude, ubude kunye nobubanzi be-dimension kunye ne-perpendicularity ye-substrate board ingaphakathi kwendawo echazwe kumzobo.

2. Inkqubo yoshicilelo lwesikrini sesilika

Okokuqala, khangela ukuba i-mesh yesikrini, uxinzelelo lwesikrini kunye nobukhulu befilimu iyahlangabezana neemfuno ezichaziweyo.

Emva koko, jonga ingqibelelo yomzobo, kwaye akukho pinhole, inotshi okanye ifilimu encamathelayo eseleyo.Jonga ngebhodi yoqobo yefoto, kwaye ubungakanani bendawo yokumisa iyahambelana, kunye nobubanzi bomgca, isithuba somgca, ubungakanani bedisk yokudibanisa okanye amanqaku oonobumba ayahambelana.

3. Ukucoca umphezulu

Ikhemikhali icocwePCBUmphezulu awuyi kuba ne-oxidation kunye nongcoliseko, kwaye uya koma emva kokucoca.

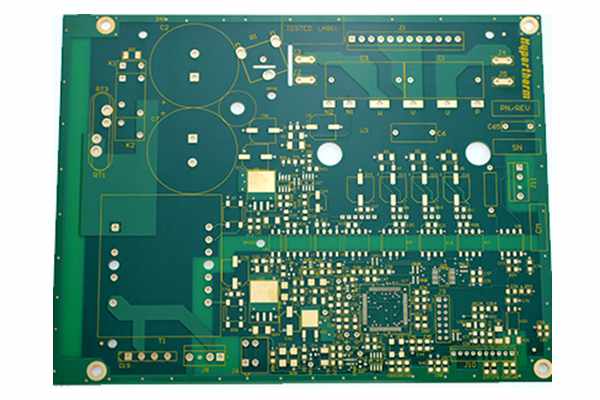

4. Ushicilelo lwesekethe

Jonga ingqibelelo yomzobo wesekethe, kwaye akukho sekethe evulekileyo, i-pinhole, inotshi okanye isiphaluka esifutshane.Jonga ngebhodi yoqobo yefoto, ubungakanani bokumisa umzobo buhambelana, ububanzi bomgca kunye nomgama womgca uyahambelana, kwaye impazamo ingaphakathi koluhlu oluvumelekileyo.

5. Ukurhabula

Jonga ingqibelelo yomzobo wesekethe, kwaye akukho sekethe evulekileyo, i-pinhole, inotshi okanye isiphaluka esifutshane.Jonga ngebhodi yoqobo yefoto, kwaye akukho kuhonjiswa (umgca ubhityile kakhulu) okanye ukufakwa ngokwaneleyo (umgca ungqindilili kakhulu).

6. Ukumelana ne-welding

Okokuqala, jonga intembeko yokumelana nemizobo ye-solder, kwaye akukho ziprinta zilahlekileyo, iiphini, iinotshi, i-inki yokubona, iindonga ezijingayo, kunye namabala e-inki angaphezulu.Iyahambelana nobukhulu bokumisa umzobo womgca, kwaye impazamo ingaphakathi koluhlu oluvumelekileyo.

Okwesibini, jonga iqondo lokunyanga le-solder ukumelana.Uluhlu lokumelana ne-solder kumphezulu womqhubi wobhedu luya kuvavanywa ngepensile, kwaye ubunzima bepensile buya kuba ngaphezu kwe-3H.

Okwesithathu, jonga amandla okudibanisa i-solder ukumelana.Intonga kwaye utsale umaleko wokuxhathisa kwi-solder kumphezulu wesikhokelo sobhedu ngeteyiphu encamathelayo.Akufuneki kubekho ukuxhathisa i-solder e-peelling kwi-tape.

7. Iimpawu zabalinganiswa ezintle nezimbi

Jonga imzobo yomzobo wamanqaku oonobumba, kwaye akukho shicilelo lungekhoyo, imingxunya, iinotshi okanye i-inki, iindonga ezijingayo, kunye namachaphaza e-inki angaphezulu.Iyahambelana nobungakanani bokumisa bemizobo yomgca, impazamo ikuluhlu oluvumelekileyo, kwaye uphawu loonobumba lunokubonwa ngokuchanekileyo.

Sinentembelo ekuboneleleni ngeyona ndibaniselwano ilungileyovula-iqhosha lenkonzo yendibano yePCB, umgangatho, ixabiso kunye nexesha lonikezelo kwi-batch yakho encinci yevolumu ye-PCB i-odolo yendibano kunye ne-Mid batch Volume PCB i-oda yendibano.

Ukuba ukhangela umenzi indibano PCB efanelekileyo, nceda uthumele iifayile zakho BOM neefayile PCB kusales@pcbfuture.com.Zonke iifayile zakho ziyimfihlo kakhulu.Siza kukuthumelela ikhowuti echanekileyo kunye nexesha lokukhokela kwiiyure ezingama-48.

Ixesha lokuposa: Dec-01-2022