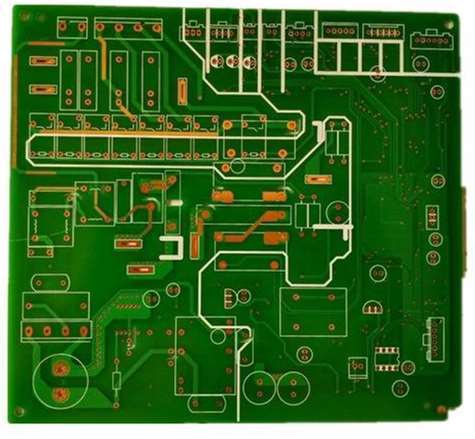

Ngophuhliso olukhawulezileyo lweshishini, iibhodi zeesekethe ziya kusetyenziswa kwiinkalo ezininzi.Xa kuziwa kwiibhodi zeesekethe, kufuneka sikhankanye iibhodi zesekethe ezithengiswayo.Ziziphi izakhono zeebhodi zeesekethe ze-soldering?Makhe sifunde indlela yokuthengisa iPCB.

Ubuchule bebhodi yesekethe ye-solder 1:

Inkqubo ye-solder ekhethiweyo ibandakanya: ukutshiza nge-flux, i-preheating board board, i-welding immersion kunye ne-drag welding.Inkqubo yokugubungela i-Flux Kwi-soldering ekhethiweyo, inkqubo yokugqoka i-flux idlala indima ebalulekileyo.Ekufudumeni kwe-welding kunye nokuphela kwe-welding, i-flux kufuneka ibe nomsebenzi owaneleyo ukuze ugweme ibhuloho kunye ne-oxidation.I-X / y manipulator ithwala ibhodi yesekethe phezulu kwi-nozzle ye-flux, kwaye i-flux itshizwe kwindawo ye-PCB ye-welding.

Ubuchule bebhodi yesekethe ye-solder 2:

Ukukhethwa kwencopho ye-microwave emva kwenkqubo yokuphinda kufakwe i-soldering, ukutshiza okuchanekileyo kwe-flux yeyona nto ibalulekileyo, kwaye uhlobo lokutshiza lwe-micro hole alunakuze lungcolise indawo engaphandle kwe-solder joint.Ubuncinane bepatheni yepatheni yedayamitha yesitshizi sendawo encinci ingaphezulu kwe-2mm, ngoko ke ukuchaneka kokuchaneka kwesitshizi esifakwe flux kwibhodi yesekethe ingaphantsi kwe-2mm ± 0.5mm ukuze kuqinisekiswe ukuba ukuguquguquka kusoloko kugqunyelelwe kwicala elidityanisiweyo.

Ubuchule bebhodi yesekethe ye-solder 3:

Owona mahluko ucacileyo phakathi kwabo kukuba indawo engezantsi yebhodi yesekethe intywiliselwe ngokupheleleyo kwi-solder yolwelo kwi-welding ye-wave peak, ngelixa i-welding ekhethiweyo, kuphela iindawo ezithile zoqhagamshelwano kunye ne-solder wave.Ngenxa yokuba ibhodi yesekethe ngokwayo iyindawo yokuqhubela ubushushu embi, ayiyi kutshisa kwaye inyibilike i-solder joints kumacandelo akufutshane kunye neendawo zebhodi yesekethe ngexesha le-welding.

Ngaphambi kwe-welding, i-flux kufuneka isetyenziswe kwangaphambili.Xa kuthelekiswa ne-soldering wave, i-flux isetyenziswa kuphela kwiindawo ezinokuthi zidityaniswe kwindawo engezantsi yebhodi yesekethe, kune-PCB yonke.Ukongeza, i-welding ekhethiweyo ifanelekile kuphela kwi-welding ye-plug-in components.I-welding ekhethiweyo yindlela entsha.Kuyimfuneko ukwazi inkqubo ye-welding ekhethiweyo kunye nezixhobo ngokucokisekileyo.

Kwi-PCBFuture, sizama ukusebenza kunye nabathengi bethu.Ukusukaprototyping PCB indibanokwimveliso epheleleyoindibano PCB turnkey, we serve as an extension to our customer’s capabilities. We are constantly enhancing our quality programs and process to meet or exceed our customer’s requirements on a continuous basis. For more information, please email to service@pcbfuture.com.

Ixesha lokuposa: Oct-23-2021