16 uhloboyePCB eqhelekileyoi-solderingiziphene

Kwinkqubo yendibano yePCB, kukho iziphene ezahlukeneyo ezihlala zivela, ezifana ne-solder yobuxoki, ukufudumeza, ukubopha ibhulorho njalo njalo.Ngezantsi PCBfuture iya kuchaza eqhelekileyoIndibano yePCBiziphene xa uthengisa ii-PCBs kunye nendlela yokuphepha ngayo.

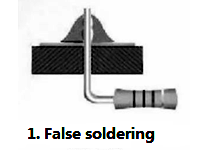

1. I-solder yobuxoki

Iimpawu zembonakalo: kukho umda omnyama ocacileyo phakathi kwe-solder kunye ne-lead yecandelo, okanye i-foil yobhedu, kwaye i-solder i-concave ukuya kumda.

Enzakala: ayisebenzi kakuhle.

Isizathu: i-lead yamacandelo ayicocwa, i-tin ayifakwanga okanye i-tin i-oxidized.Ibhodi yesekethe eprintiweyo ayicocwa, kwaye umgangatho wokutshiza i-flux ayilungile.

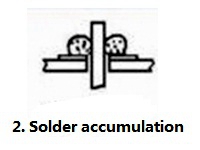

2. Ukuqokelela i-solder

Iimpawu zokubonakala: isakhiwo esidibeneyo se-solder sikhululekile, simhlophe kwaye singenasiphelo.

Ubungozi: ukungonelanga kwamandla oomatshini kunokubangela i-welding yobuxoki.

Isizathu: umgangatho ombi we-solder.Ubushushu be-welding alanelanga.Xa i-solder ingaqiniswanga, icandelo lokukhokela likhululekile.

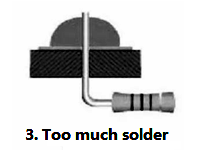

3. I-solder eninzi kakhulu

Iimpawu zembonakalo: indawo ye-solder i-convex.

Ubungozi: i-solder iyachithwa kwaye iziphene zisenokungabonakali lula.

Isizathu: ukusebenza okungalunganga ngexesha le-soldering.

4. I-solder encinci kakhulu

Iimpawu zokubonakala: indawo ye-welding ingaphantsi kwe-80% ye-pad, kwaye i-solder ayifaki inguqu egudileyo.

Ubungozi: ukungonelanga kwamandla oomatshini.

Isizathu: ukuhamba kwe-solder kubi okanye ukuhoxiswa kwe-solder kwangaphambi kwexesha.Ukuhamba okungonelanga.Ixesha le-welding lifutshane kakhulu.

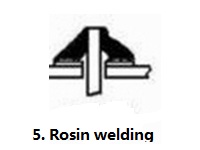

5. I-rosin welding

Iimpawu zokubonakala: kukho i-rosin slag kwi-weld.

Ukwenzakala: Amandla angonelanga, ukuqhuba kakubi, ngamanye amaxesha ukulayita nokuvala.

Isizathu: Baninzi kakhulu oomatshini bokuwelda okanye ukungaphumeleli kwewelder.Ixesha le-welding elaneleyo kunye nokufudumeza.Ifilimu ye-oxide engaphezulu ayizange isuswe.

6. Ubushushu obugqithisileyo

Iimpawu zembonakalo: i-solder emhlophe edibeneyo, ayikho i-metallic luster, i-rough surface.

Ingozi: i-pad kulula ukuyikhupha kwaye amandla ayancipha.

Isizathu: amandla entsimbi ye-solder makhulu kakhulu, kwaye ixesha lokufudumala lide kakhulu.

7. Ukuwelda okubandayo

Iimpawu zembonakalo: Umphezulu we-granular, kwaye ngamanye amaxesha kunokubakho iintanda.

Ubungozi: Amandla aphantsi kunye nokungahambi kakuhle.

Isizathu: i-solder iyashukunyiswa ngaphambi kokuba iqine.

8. Ukungena kakubi

Iimpawu zembonakalo: ujongano phakathi kwe-solder kunye ne-weldment inkulu kakhulu kwaye ayigudi.

Ubungozi: Amandla aphantsi, akukho ukufikelela okanye ixesha lokuvula kunye nokucima.

Isizathu: i-weldment ayicocwanga.I-Flux ayonelanga okanye ikumgangatho ophantsi.I-weldment ayishushu ngokupheleleyo.

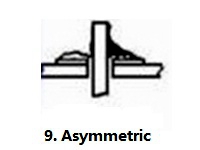

9. Asymmetric

Iimpawu zokubonakala: i-solder ayidluli phezu kwe-pad.

Ukwenzakala: Amandla angonelanga.

Isizathu: i-solder ayinamanzi amdaka.Ukuguquguquka okunganelanga okanye umgangatho ophantsi.Ukufudumeza okungonelanga.

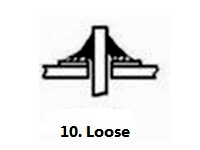

10. Ekhululekile

Iimpawu zenkangeleko: Ucingo okanye icandelo lelothe lingashukunyiswa.

Ubungozi: Imbi okanye ayiqhutywanga.

Isizathu: phambi kokuba i-solder iqine, ucingo olukhokelayo luyahamba lubangele i-voids.Ilothe ayilungiswanga kakuhle.

11. Cusp

Iimpawu zembonakalo: zibukhali.

Ubungozi: inkangeleko embi, kulula ukwenza ibhulorho

Isizathu: i-flux encinci kunye nexesha elide lokufudumeza.I-angle yokushiya intsimbi ye-soldering ayifanelekanga.

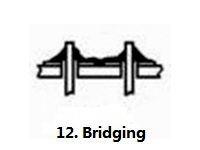

12. Ukudibanisa

Iimpawu zokubonakala: iingcingo ezikufutshane zixhunyiwe.

Ubungozi: Isiphaluka esifutshane sombane.

Isizathu: solder kakhulu.I-angle engafanelekanga yokurhoxiswa kwentsimbi ye-soldering.

13. Umngxuma wokuqhafaza

Iimpawu zokubonakala: ukuhlolwa okubonakalayo okanye i-amplifiers yamandla aphantsi inokubona imingxuma.

Ubungozi: amandla angonelanga, ijoyinti ye-solder kulula ukugrumba.

Isizathu: umsantsa phakathi kwelethe kunye nomngxuma wepadi mkhulu kakhulu.

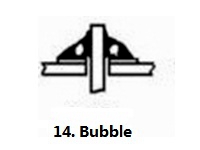

14. Ibhalumula

Iimpawu zokubonakala: kukho i-solder ephefumula umlilo kwingcambu yesikhokelo, kwaye i-cavity ifihliwe ngaphakathi.

Ukulimala: ukuqhutyelwa kwexeshana, kodwa kulula ukubangela ukuqhuba kakubi ixesha elide.

Isizathu: i-gap phakathi kwesikhokelo kunye ne-welding disc hole inkulu.Ukungenwa kwelothe engalunganga.Ixesha le-welding ye-double-sided plugging ngokusebenzisa imingxuma elide, kwaye umoya kwimingxuma uyanda.

15. Ifoyile yobhedu ejijekileyo

Iimpawu zokubonakala: i-foil yobhedu ihlanjululwe kwibhodi eprintiweyo.

Ubungozi: I-PCB yonakele.

Isizathu: ixesha le-welding lide kakhulu kwaye ubushushu buphezulu kakhulu.

16. Zihlutywe

Iimpawu zokubonakala: i-solder joints ikhupha kwi-foil yobhedu (kungekhona i-copper foil kunye ne-PCB).

Ubungozi: Vula isekethe.

Isizathu: intsimbi embi yokwaleka kwiphedi.

I-PCBFuture ibonelela ngazo zonke iinkonzo zendibano ye-PCB ebandakanyayo, kubandakanywa ukwenziwa kwe-PCB, ukufunwa kwecandelo kunye nendibano ye-PCB.YethuInkonzo yePCB yeTurnkeykuphelisa imfuno yakho yokulawula ababoneleli abaninzi ngamaxesha amaninzi, okukhokelela ekongezeni kokusebenza kunye nokusebenza kweendleko.Njengenkampani eqhutywa ngumgangatho, siphendula ngokupheleleyo kwiimfuno zabathengi, kwaye sinokubonelela ngeenkonzo ngexesha kunye nezomntu ngamnye ukuba iinkampani ezinkulu azikwazi ukuxelisa.Sinokukunceda ukuba uphephe iziphene ze-PCB zokuthengisela kwiimveliso zakho.

Ixesha lokuposa: Nov-06-2021