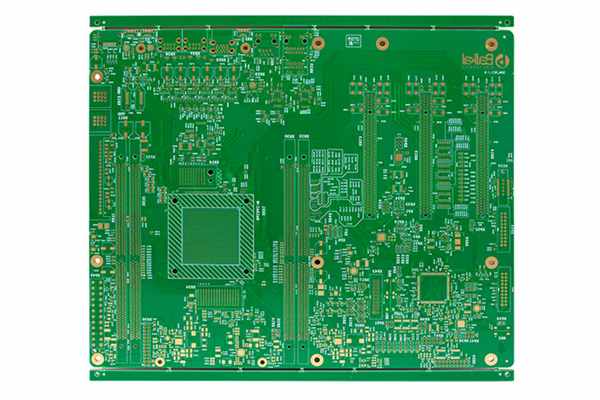

Kwi-PCB proofing, umaleko we-lead-tin resist is pre-plated kwi-copper foil part ukuze igcinwe kumaleko angaphandle ebhodi, oko kukuthi, inxalenye yegraphic yesekethe, emva koko ifoyile yobhedu eseleyo ifakwe ngokwekhemikhali. kude, okubizwa ngokuba yi-etching.

Ngoko, kwiUbungqina bePCB, zeziphi iingxaki ekufuneka ziqwalaselwe kwi-etching?

Imfuno yomgangatho wokuchongwa kukukwazi ukususa ngokupheleleyo zonke iileyile zobhedu ngaphandle kwe-anti-etching layer.Ukuthetha ngokuthe ngqo, umgangatho we-etching kufuneka ubandakanye ukufana kobubanzi bocingo kunye nomgangatho wokubetha kwecala.

Ingxaki ye-etching yecala isoloko iphakanyiswa kwaye ixoxwe ekufakeni.Umlinganiselo we-etch ububanzi ukuya kubunzulu be-etch kuthiwa yi-etch factor.Kwishishini lesekethe eprintiweyo, idigri encinci ye-etch yecala okanye i-etch factor ephantsi yeyona yanelisayo.Ubume besixhobo sokutsala kunye neengoma ezahlukeneyo zesisombululo se-etching ziya kuchaphazela i-etching factor okanye i-side etching degree.

Ngeendlela ezininzi, umgangatho we-etching ukhona kwakudala ngaphambi kokuba ibhodi yesekethe ingene kumatshini wokubhala.Ngenxa yokuba kukho unxibelelwano olusondeleyo lwangaphakathi phakathi kweenkqubo ezahlukeneyo zobungqina be-PCB, akukho nkqubo engachatshazelwanga zezinye iinkqubo kwaye ayichaphazeli ezinye iinkqubo.Uninzi lweengxaki ezichongiweyo njengomgangatho we-etch bezikhona kwinkqubo yokuhluba nangaphambili.

Ukuthetha ngokwethiyori, ubungqina be-PCB bungena kwinqanaba le-etching.Kwindlela yokulinganisa i-electroplating yepateni, imeko efanelekileyo kufuneka ibe: isixa sobunzima bobhedu kunye ne-lead tin emva kwe-electroplating akufanele idlule ubukhulu befilimu ye-electroplating photosensitive film, ukwenzela ukuba ipateni ye-electroplating igutyungelwe ngokupheleleyo kumacala omabini efilimu.Iibhloko "zodonga" kwaye zifakwe kuyo.Nangona kunjalo, kwimveliso yokwenyani, ipateni yokwambathisa ityebe kakhulu kunendlela yefotosensitive;ekubeni ukuphakama kwengubo kudlula ifilimu ye-photosensitive, kukho i-trend of lateral accumulation, kunye ne-tin okanye i-lead-tin ukumelana ne-lead egqunywe ngaphezu kwemigca idlulela kumacala omabini, yenze "Edge", inxalenye encinci yefilimu ye-photosensitive. igqunywe phantsi "komphetho"."Umphetho" owenziwe nge-tin okanye i-lead-tin yenza ukuba akunakwenzeka ukususa ngokupheleleyo ifilimu ye-photosensitive xa ususa ifilimu, ushiya inxalenye encinci "yeglue eseleyo" phantsi "komphetho", okubangelwa ukuchithwa okungaphelelanga.Imigca yenze "iingcambu zobhedu" kumacala omabini emva kokukrolwa, nto leyo icuthe isithuba somgca, ibangeleibhodi eprintiweyoukungaphumeleli ukuhlangabezana neemfuno zabathengi kwaye kusenokukhatywa.Iindleko zemveliso yePCB zonyuka kakhulu ngenxa yokwaliwa.

Kwi-PCB proofing, xa kukho ingxaki kwinkqubo yokufaka, kufuneka ibe yingxaki yebhetshi, eya kuthi ekugqibeleni ibangele iingozi ezinkulu ezifihlakeleyo kumgangatho wemveliso.Ngoko ke, kubaluleke kakhulu ukufumana indawo efanelekileyoPCB proofing umenzi.

I-PCBFuture yakha igama lethu elihle kwishishini lenkonzo ye-PCB ye-turnkey epheleleyo yendibano ye-PCB yomzekelo kunye nomthamo ophantsi, indibano ye-PCB yevolumu ephakathi.Yintoni ekufuneka abathengi bethu bayenze kukuthumela iifayile zoyilo zePCB kunye neemfuno kuthi, kwaye sinokukhathalela wonke umsebenzi.Sinakho ngokupheleleyo ukubonelela ngeenkonzo zePCB eziguquguqukayo kodwa sigcine iindleko zizonke kuhlahlo lwabiwo-mali lwakho.

Ukuba ujonge umenzi wendibano weTurnkey PCB ofanelekileyo, nceda uthumele iifayile zakho zeBOM kunye neefayile zePCB kusales@pcbfuture.com. Zonke iifayile zakho ziyimfihlo kakhulu.Siza kukuthumelela ikhowuti echanekileyo kunye nexesha lokukhokela kwiiyure ezingama-48.

Ixesha lokuposa: Dec-09-2022