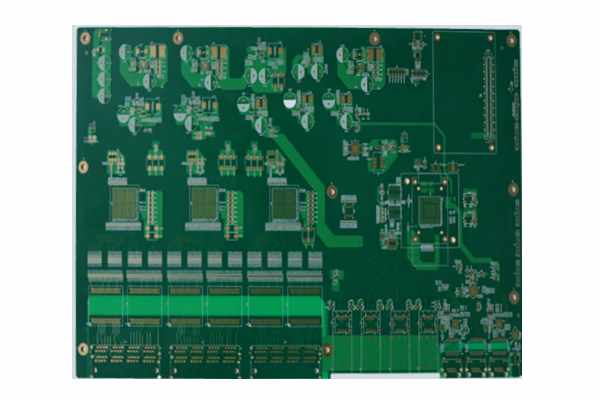

Ngophuhliso lwe-miniaturization kunye nokuchaneka kweemveliso ze-elektroniki, iUkwenziwa kwendibano yePCBkunye noxinaniso lwendibano olusetyenziswa ziiplanti zokusetyenzwa kwe-elektroniki luya phezulu nangaphezulu, amalungu e-solder kwiibhodi zesekethe aya encipha kwaye encipha, kwaye oomatshini, imithwalo yombane kunye ne-thermodynamic abayithwalayo iya phezulu nangaphezulu.Iya isiba nzima kwaye iimfuno zozinzo nazo ziyanda.Nangona kunjalo, ingxaki yokusilela kokudityaniswa kwe-solder ye-PCB nayo iya kuqubisana neyona nkqubo yokucubungula.Kuyimfuneko ukuhlalutya kunye nokufumanisa isizathu sokuphepha ukungaphumeleli kokubambisana kwe-solder ukuba kungenzeki kwakhona.

Ke namhlanje, siya kukwazisa kuwe izizathu eziphambili zokusilela kwindibano ye-PCB yokulungiswa kwamalungu e-solder.

Ezona zizathu ziphambili zokungaphumeleli kwendibano yePCB yokulungiswa kwamalungu e-solder:

1. Izikhonkwane zecandelo elibi: i-plating, ukungcola, i-oxidation, i-coplanarity.

2. Iipads zePCB ezimbi: i-plating, ungcoliseko, i-oxidation, i-warpage.

3.Iziphene zekhwalithi ye-Solder: ukubunjwa, ukungcola okungaphantsi komgangatho, i-oxidation.

4. Iziphene zekhwalithi ye-Flux: i-flux ephantsi, i-corrosion ephezulu, i-SIR ephantsi.

5. Inkqubo yokulawulwa kweparameter iziphene: ukuyila, ukulawula, izixhobo.

6. Ezinye izinto ezincedisayo iziphene: i-adhesives, i-agent yokucoca.

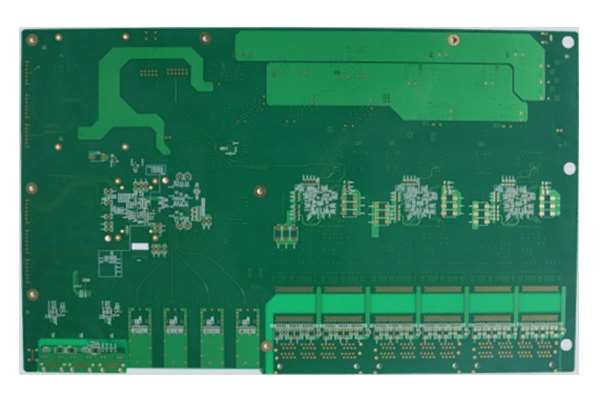

Iindlela zokwandisa uzinzo kwi-PCB yendibano ye-solder joints:

Uvavanyo lozinzo lwe-PCB yendibano ye-solder joints lubandakanya uvavanyo lozinzo kunye nohlalutyo.

Kwelinye icala, injongo yayo kukuvavanya nokuchonga inqanaba uzinzo PCB indibano izixhobo zesekethe ezidityanisiweyo, kunye nokubonelela parameters kuyilo uzinzo umatshini wonke.

Kwelinye icala, kwinkqubo yeindibano PCBukucubungula, kuyimfuneko ukuphucula ukuzinza kwamalungu e-solder.Oku kufuna uhlalutyo lwemveliso engaphumelelanga, ukufumana indlela yokungaphumeleli, kunye nokuhlalutya unobangela wokungaphumeleli.Injongo kukuhlaziya kunye nokuphucula inkqubo yoyilo, iiparamitha zesakhiwo, inkqubo ye-welding, kunye nokuphucula isivuno sokusetyenzwa kwendibano yePCB.Imowudi yokungaphumeleli kwendibano ye-solder ye-PCB sisiseko sokuqikelela ubomi bomjikelo kunye nokuseka imodeli yayo yezibalo.

Ngelizwi, Sifanele siphucule ukuzinza kwamalungu e-solder kunye nokuphucula isivuno seemveliso.

I-PCBFuture izimisele ukubonelela ngomgangatho ophezulu kunye noqoqoshoInkonzo yendibano ye-One-Stop PCBkubo bonke abathengi behlabathi.Ngolwazi oluthe vetshe, nceda u-imeyilele kuservice@pcbfuture.com.

Ixesha lokuposa: Oct-26-2022