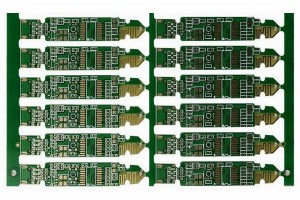

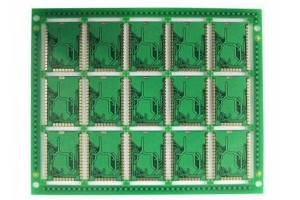

Ukuze kuphuculwe ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko zemveliso kwiIndibano yePCBinkqubo, iibhodi zesekethe engenanto ngokuqhelekileyo ukwenza panel kwimveliso, nto leyo enokwenza lula PCBA processing plant ukuphumeza chip welding.Oku kulandelayo kuya kuthetha malunga neendlela eziqhelekileyo zepaneli kunye nemigaqo yebhodi yesekethe.

Umgaqo-siseko we-PCB wepaneli:

1. Ubungakanani bebhodi yepaneli ye-PCB ububanzi ≤ 300mm (umgca weFuji);ukuba ifuna unikezelo oluzenzekelayo, ubungakanani bePCB kufuneka ≤ 125mm(W) × 180mm(L).

2. Imilo ye-PCB iya kuba kufutshane nesikwere kangangoko kunokwenzeka, kwaye kucetyiswa ukuba ibhodi yokudibanisa yi (2*2,3 *3,4* 4) kwiqela ngalinye.

3. Ifreyim yangaphandle (i-clamping edge) yebhodi yesekethe iya kwamkela uyilo oluvaliweyo lweloop ukuqinisekisa ukuba iphaneli yePCB ayisayi konakala emva kokuba ilungisiwe.

4. Umgama ophakathi kwebhodi yePCB encinci uya kulawulwa kwi-75mm ~ 145mm.

5. Akuyi kubakho izixhobo ezikhulu okanye izixhobo eziphumayo kufutshane nendawo yokudibanisa phakathi kwesakhelo sangaphandle sebhodi yokuhlanganisa kunye nebhodi encinci yangaphakathi, kwaye kuya kubakho isithuba esikhulu kune-0.5mm phakathi kwamacandelo kunye nomphetho webhodi yePCB qinisekisa ukusebenza okuqhelekileyo kwesixhobo sokusika.

6. Kwiikona ezine zesakhelo sangaphandle se-PCB, imingxuma emine yokumisa ivuliwe kwaye i-diameter yomngxuma yi (4mm ± 0.01mm);Amandla omngxuma aya kuba phakathi ukuqinisekisa ukuba akayi kuphuka ngexesha lenkqubo yokulayishwa kunye nokukhulula;Ububanzi bomngxuma kunye nokuchaneka kwendawo kuya kuba phezulu, kwaye umngxuma uya kuba mpuluswa.

7. Ibhodi nganye encinci kwi-PCB kufuneka ibe ubuncinane imingxuma emithathu yokumisa, i-3 ≤ umngxuma ububanzi ≤ 6mm, kunye ne-wiring okanye i-SMT ayivumelekanga ngaphakathi kwe-1mm ye-edge positioning hole.

8. Xa ubeka i-reference positioning point, indawo ye-welding enganyangekiyo i-1.5mm enkulu kunendawo yokumisa idla ngokugcinwa kwindawo yokumisa.

9. Amacandelo amakhulu aya kunikwa izithuba zokubeka okanye imingxuma yokubeka, njengale: imakrofoni, i-battery interface, i-microswitch, i-headset interface, i-motor, njl.

Iindlela eziqhelekileyo zePCB eziqhagamshelwe kwindawo yolawulo:

1, V-CUT

I-V-CUT ithetha ukuba iibhodi ezininzi okanye ibhodi enye inokudityaniswa kwaye idibaniswe kunye, kwaye emva koko i-V-groove inokunqunyulwa ngomatshini we-V-CUT phakathi kweebhodi emva kokucubungula kwe-PCB, enokwaphulwa ngexesha lokusetyenziswa.Yeyona ndlela idumileyo namhlanje.

2. Ukubetha umjelo

Ukubetha kubhekisa ekugayeni okungenanto phakathi kweepleyiti okanye iipleyiti zangaphakathi ezinomatshini wokungqusha njengoko kufuneka, nto leyo ilingana nokugrumba ngaphandle.

3. Umngxuma wesitampu

Oku kuthetha ukuba sebenzisa umngxuma omncinane ukudibanisa ibhodi yePCB, ekhangeleka ngathi yimilo yesawtooth kwisitampu, ngoko ibizwa ngokuba likhonkco lomngxuma wesitampu.Ikhonkco lomngxunya wesitampu lifuna i-burr yolawulo oluphezulu ejikeleze ibhodi, oko kukuthi umngxuma wesitampu omncinci kuphela onokusetyenziswa ukubuyisela umgca weV.

Ufuna ukwazi ngakumbi, nceda ucofe: www.PCBfuture.com

Ixesha lokuposa: Jan-13-2022